How to Make Custom Dry Cockpit Cushions

Few things are more annoying than sitting on an unexpectedly soggy cushion, and boat cockpit cushions are particular offenders. Solve the problem permanently with waterproof, ventilated built-ins.

Tools: measuring rule or tape, power saw or handsaw, carpenters' square, hammer, electric drill or brace and bit, paintbrush, sharp utility knife, sharp scissors, staple gun.

Advertisement

材料: 1/2 × 3/4-inch parting stop stock, 5/8-inch brads, 3/8-inch exterior-grade plywood, high-gloss polyurethane varnish, 4-inch-thick heavy-duty closed-cell foam, waterproof fabric or vinyl, copper-clad heavy-duty staples.

Time: about 4 hours per cushion, plus drying time.

Choose the materials for your cushions carefully; everything you use must be waterproof and noncorroding. Be sure to buy closed-cell foam -- the open-cell kind absorbs water.

For each cushion you're replacing, measure the old cushion carefully. Plan the frame of the cushion to be 1 inch smaller than the cushion each way, and measure and cut a piece of 3/8-inch exterior plywood exactly to that size; use a carpenters' square to make sure your cuts are straight.

Cut four pieces of 1/2 × 3/4-inch parting stop stock to form the sides of the frame, with two pieces the same length as the sides of the plywood square and two pieces cut short enough to butt between the other pieces at the corners of the boat cushion frame. Nail the strips of parting stop into place on the sides of the plywood to form a shallow tray; use 5/8-inch brads to attach the strips to each other at the corners and to the plywood backing of the frame.

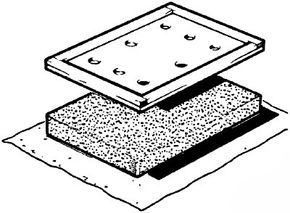

When the frame of the cushion is assembled, drill four to eight 1/4- to 1/2-inch ventilation holes in the plywood base, depending on the size of the frame. Use an electric drill or a brace and bit. Varnish the completed frame thoroughly with high-gloss polyurethane varnish, covering the wood generously to prevent it from delaminating. Varnish the plywood base on the edges and both sides, being careful to cover the insides of the drilled ventilation holes; varnish all exposed surfaces of the parting stop frame. Let the frame dry completely, as directed by the manufacturer, and apply a second generous coat of varnish; let dry again.

For each cushion, measure and cut 4-inch-thick heavy-duty closed-cell foam exactly to size with a sharp utility knife. The foam should be 1 inch larger than the plywood frame each way. Using the foam as a pattern, cut a piece of waterproof fabric or vinyl about 7 inches longer than the foam all around, so that it can be folded over the foam toward the middle of the cushion and stapled into place. Make sure to leave enough fabric to cover the sides of the frame on all sides.

Spread the fabric on the floor and center the foam on it; then set the plywood base of the cushion on top of the foam, frame side up and flat side to the foam. Starting at one corner, fold the fabric up over the foam and the frame. Turn the cut edge under and staple the fabric into place on the plywood inside the parting stop frame, using a staple gun and copper-clad heavy-duty staples. Pleat the corners of the fabric in to miter them neatly as you work. Repeat to fasten the opposite side of the fabric, pulling it firm but not flattening the foam; then staple the other two sides.

Follow the same procedure for each cushion you're replacing, being careful to make the new cushion's exactly the same size as the old. To install the cushions, just set them in place in the cockpit.

As captain of your boat, you have to make sure all its parts are in working order. Perhaps the most important of these is the outboard motor. In the next section, learn how to poperly inspect, maintain, and tune up your boat's motor.

For tips on caring for and repairing other types of sports equipment, try the following links:

- Learn how to keep your skis and ski poles in top condition atHow to Maintain Skis.

- For maintenance tips for your bicycle, including how to patch a tire, replace a chain or spoke, and tune up the brakes, readHow to Repair a Bicycle.

- If you're a camper, check outHow to Make and Repair Camping Equipmentto learn how to fix a damaged tent, make a tarp, and more.

- How to Maintain Golf Equipmentleads you step-by-step through regripping and refinishing a golf club.

- Skateboarders can get valuable information on taking care of their boards atHow to Maintain a Skateboard.